Preliminary trial test

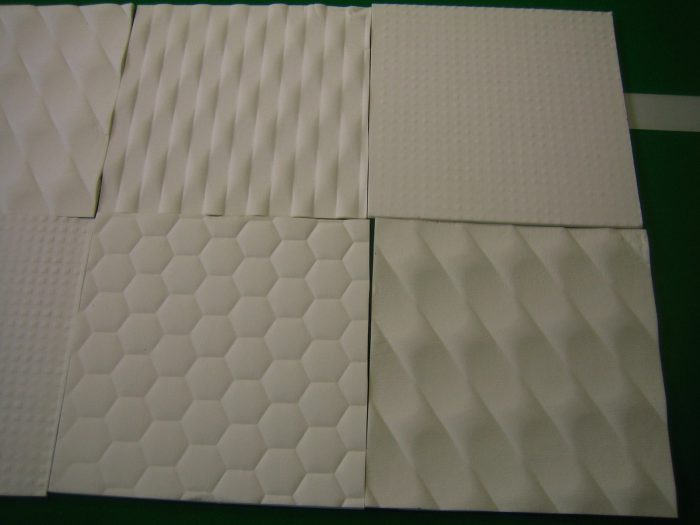

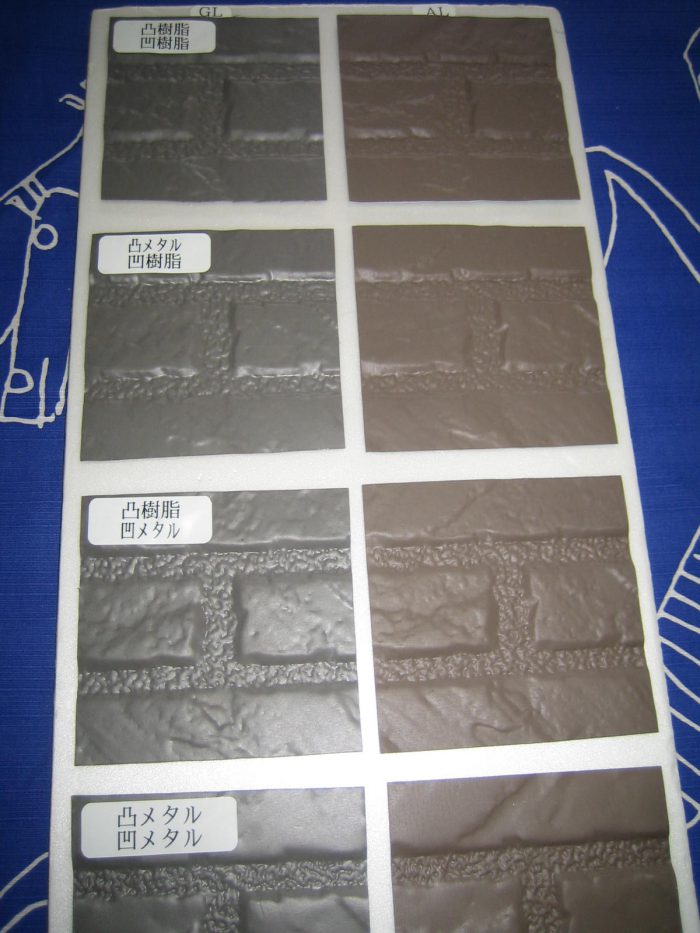

Before producing an embossing roller prototype, we perform plain prototyping using a trial press mold to show what negative molds and positive molds are placed on customer-supplied material.

Cost for this preliminary test will be incurred, but this enables a low-cost check.

It will show the appearance of the completed product, possible breaking during molding, and expansion.

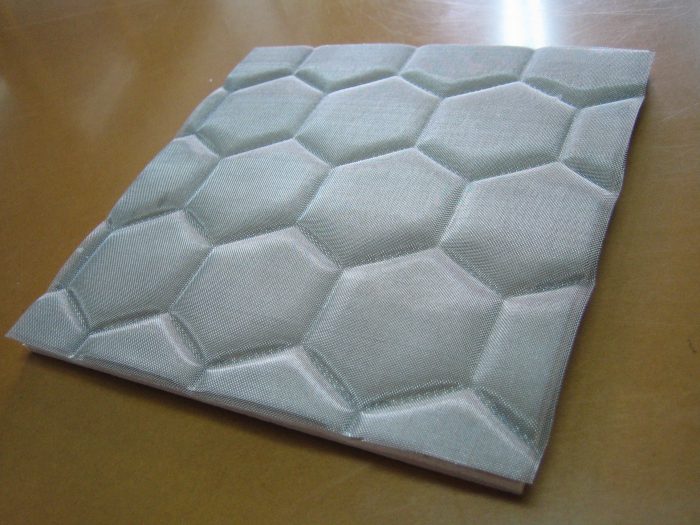

Molded composite mesh sheet |

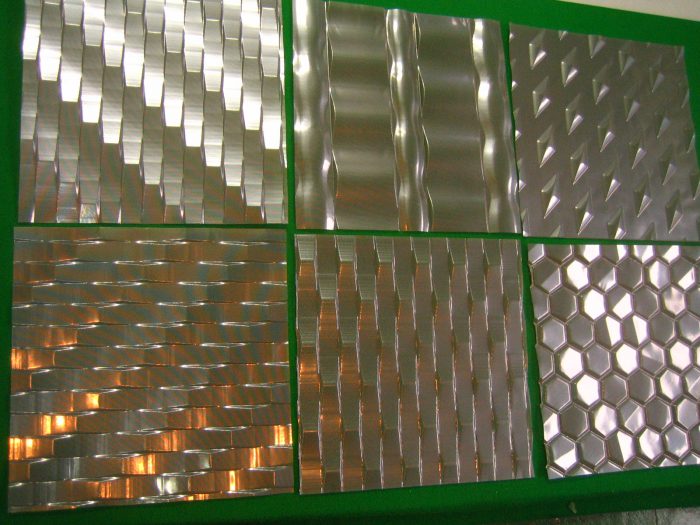

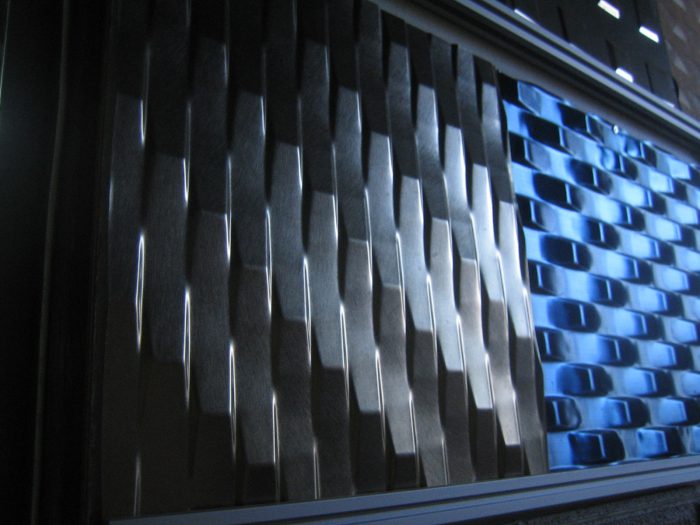

Molded laminated steel sheets |

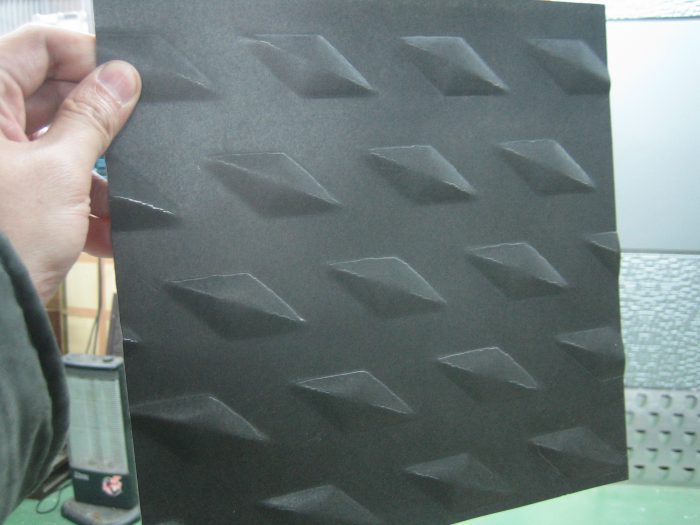

Molded magnesium sheet |

Molded thin etching sheets |

Molded nonwoven mats |

Molded specially coated steel sheet |

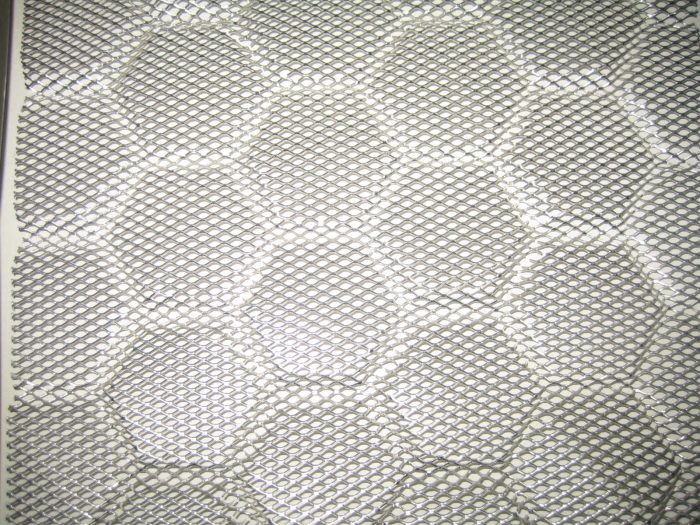

Molded expandable metal sheet |

Molded natural wood veneer composite sheet |

Molded steel sheet reproducing Japanese traditional gold brocade pattern |

Molded silicate calcium board |

Molded punched metal sheets |

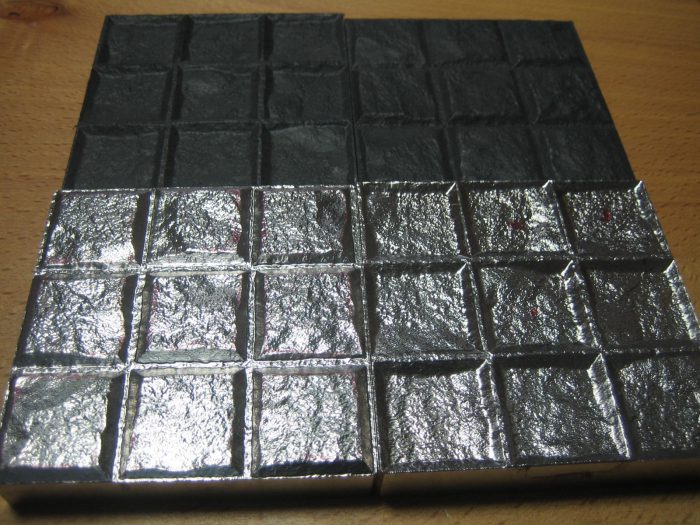

Molded colored SUS sheets |

Evaluation prototyping test

Prototyping press molds

BPrototyping by a press mold is available from a minimum size of 100 mm × 100 mm.

A mold using special resin is produced with a short lead time.

If the actual material used for molding is supplied, we can perform prototyping.

Prototyping press system, 300 tons |

|

|

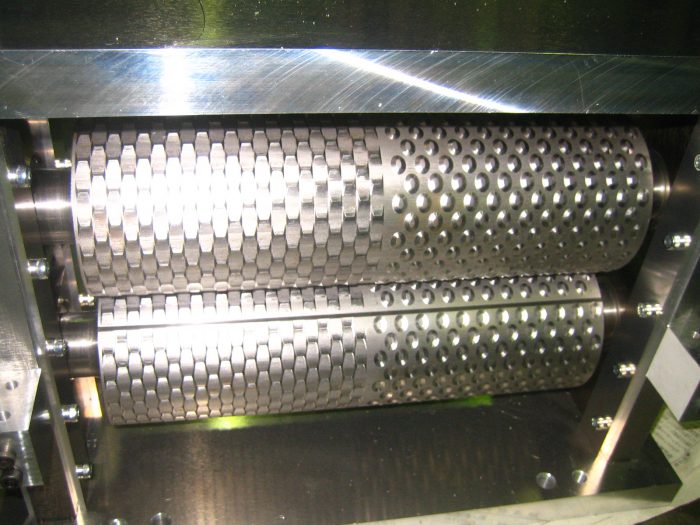

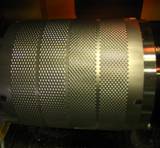

Prototyping embossing roller

We will produce a trial embossing roller to suit our embossing test system and perform prototyping

|

|

|

Prototyping press system

|

Hydraulic press system for press prototyping (Product of Osaka Jack, with a capacity of 600 tons) We have introduced a hydraulic press system for the prototyping press (product of Osaka Jack, with a capacity of 600 tons). The maximum molding size has been enlarged to 850 mm × 700 mm. |

|

Hydraulic press system for the prototyping press (product of Osaka Jack, with a capacity of 300 tons) Hydraulic press system for the prototyping press (product of Osaka Jack, with a capacity of 300 tons). The maximum molding size of this system is 800 mm × 550 mm. |

|

Hydraulic press system for the prototyping press (product of Osaka Jack, with a capacity of 100 tons) We provide a hydraulic press system for the prototyping press (product of Osaka Jack, with a capacity of 100 tons) with a hot plate unit, enabling a heating press test. The maximum molding size is 300 mm × 300 mm. |

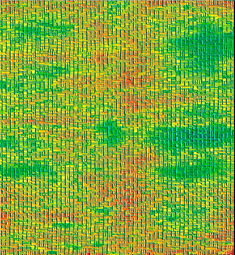

Evaluation of molded products

|

By digitizing molded products, we perform data analysis to visualize differences between actual mold data and molded products. |

| For the above-mentioned prototyping mold production, mold prototyping, molded product evaluation and data analysis, we will be pleased to provide a detailed explanation. Please send us a request. |