We reproduce the grain of natural materials with high fidelity by 3D-design digital data.

It was conventionally difficult to plot the structurally discontinuous, random grain that natural materials, such as stones and woods, have or to reproduce it automatically.

Our reverse engineering system highly precisely performs the 3D measurement of (digitizes) the extremely fine grain of such materials as genuine stones, woods and Japanese traditional paper, and it edits and enhances the data by various methods to be useful for industrial products, enabling the full automatic processing of construction-material press molds, patterned embossing rollers and design models.

Production can be performed based totally on digital data, realizing a wide range of digitalization benefits, such as a complete repeat production of a mold or roller using design modification control, CG-based coating verification, catalog-data production, registered design data, and verification through comparison between molded products and original data.

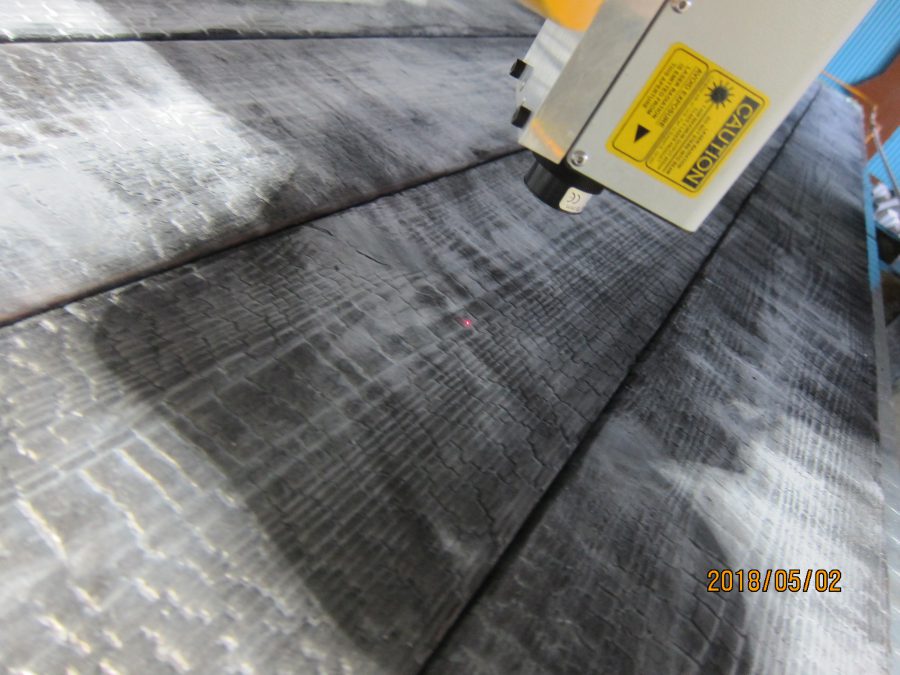

(1) Digitizing

|

To precisely measure natural woodgrain, coordinates at about 250,000 to 500,000 points need to be identified in a 100 mm × 100 mm area. |

|

(2) Design production

| The design is produced from the digitized texture data to suit the designated layout. Data editing is possible according to your request. |  |

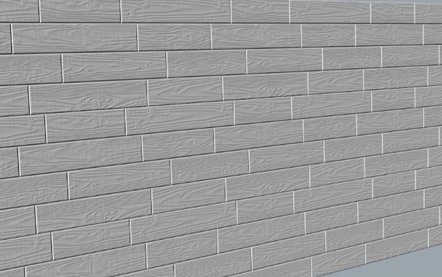

(3) CG-based verification

| The completed design is verified by computer graphics (CG). If it is necessary to verify the design with an actual material, a chemical wood model can be produced. |  |

(4) Conversion into NC data

| The approved data is converted into NC data to produce a press mold or embossing roller. The NC data is sent to machine tools, and the mold or embossing roller is produced by direct carving. |  |