|

|

Embossing rollers typically have the following applications and characteristics.

| Material | Resin | |

| Metal (iron or aluminum) | ||

| Shape and item | Negative molds(mold shape only) | Embossing roller |

| Positive molds and negative molds (upper and lower molds) | Matched steel embossing | |

| Positive molds and negative molds (upper and lower molds; fine patterns) | Micro-embossing | |

| Special | Heating roller | |

1)Embossing roller for ceramic exterior material

| Application | For ceramic exterior material (Patterns are marked on the extruded ceramic base material.) | |

| Characteristics | Suited for deep, complicated patterns | |

| Shape | Negative molds (mold shape) | |

| Material | Resin | Flexibly and speedily accommodates design changes and can be used for mass production |

| Partial processing and modification available | ||

| Recyclable as the resin part is changeable | ||

| Metal (aluminum) |

Can be chrome-plated (surface reinforcement by chrome plating) |

|

|

|

|

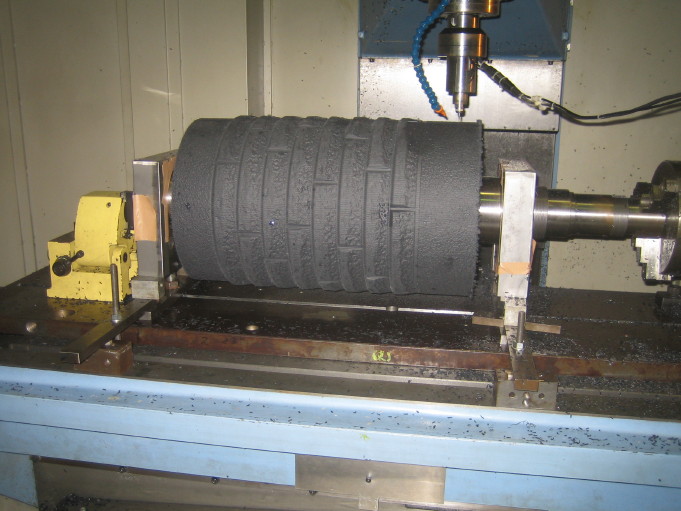

Resin embossing roller |

Aluminum embossing roller being processed |

2)Embossing rollers for paper manufacturing

| Application | For paper manufacturing | |

| Characteristics | Applicable to a wide range of applications, from fine dimples to the natural texture of Japanese traditional paper | |

| Shape | Negative molds (mold shape) plus elastic rubber roller, positive molds and negative molds (upper and lower molds), special (heating roller) | |

| Material | Resin | Applicable to mass production |

|

Metal (iron or aluminum) |

Applicable to heating rollers |

|

It is possible to have the finishing checked in advance, using a 100 × 100 mm plain press, after the design is determined and CG is approved.

|

|

|

Resin embossing rollers |

Matched steel resin embossing rollers |

3)Embossing rollers for resin film

| Application | For resin film | |

| Characteristics | Fine patterns can be reproduced. | |

| Shape | Negative molds (mold shape) | |

| Material | Metal (aluminum, brass, etc.). Can be used for hot methods. | |

|

|

| Brass embossing rollers can reproduce fine patterns. | Duralumin embossing roller |

4)Micro-embossing (micromachining technology)

We are committed to developing various micro-embossing technologies.

| Application | For micromachining | |

| Characteristics | Applicable to various patterns, such as micro-dotting, V-notching and hairline machining | |

| Shape | Negative molds (mold shape), and positive molds and negative molds (upper and lower molds, super-fine) | |

| Material | Aluminum | JIS 7075, JIS 5052, etc. Can be treated with alumite treatment and Teflon. |

| Iron | SCM steel, die steel, etc. Can be treated by vacuum hardening, Tufftride treatment, and nitriding. | |

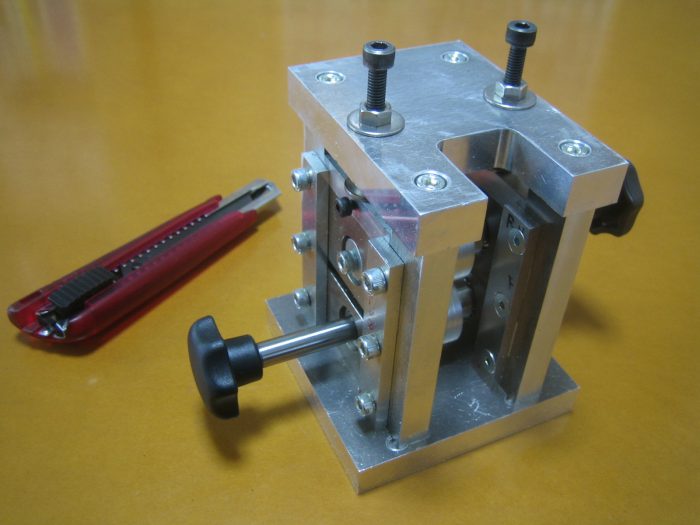

Production of a micro-embossing system

We can supply a plain embossing system suited for your embossing rollers. This system will enable you to verify the desktop evaluation at hand.

|

|

Please send us inquiries for more details.

Most of our products involve newly developed technology.

We start equipment production, prototyping, joint development or entrusted research after signing a non-disclosure contract where necessary.

5)Embossing rollers for the mass production of metal exterior material

| Application | For the mass production of metal exterior material | |

| Characteristics | Applicable to mass production of 6-mm pattern depth | |

| Shape | Negative molds and positive molds (upper and lower molds) | |

| Material | Resin, metal | |

Prototyping using a trial press of 300 × 300 or 500 × 500

Please send an inquiry for more details.

|

|

| NDeep-drawing resin embossing rollers are being processed. | Unprecedently deep drawing is available. |

6)Difficult-to-machine material processing

We are trying to micromachine extremely hard, difficult-to-machine material (presses and embossing rollers).

We machine quenched die steel as an example. The maximum hardness is about HRC55. Please send an inquiry for more details.

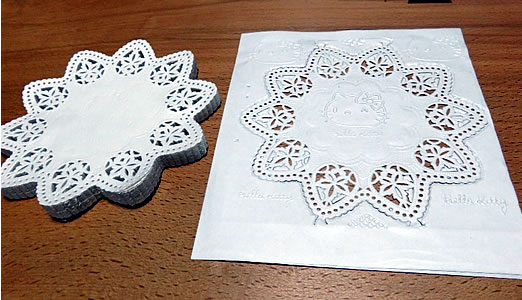

7)Lace paper embossing roller

This roller provides a form on a sheet while cutting into fine shapes.

The paper is normally placed under a whole cake or used to decorate desserts. The transfer of a detailed design and cutting can be performed.

1.Before the roller is produced, prototyping pressing is performed (duralumin mold).

|

2.Lace-paper embossing roller

|

|

3.Lace-paper (completed product)

|

|

|