Process of the production of molds and embossing rollers

Determination

of

the specifications

- 1Inquiry

- ▶︎Please make your inquiries by telephone or by email.

- 2Communication on specifications

- We will receive your expected molding methods, materials, designs, etc

- 3Prototyping and verification

- ▶︎A prototype is produced by means of a miniature mold to confirm feasibility. (The cost for prototyping will be invoiced.)

Design

determination

- 4Design model

- ▶︎Several methods are available for the design-model preparation.

- 5Data editing

- ▶︎The design model will be digitalized and edited.

- 6Verification by computer graphics (CG)

- ▶︎Various characteristics will be verified by CG.

- 7Your approval

- For your approval, CG or a machined chemical-wood model will be presented.

Mold

production

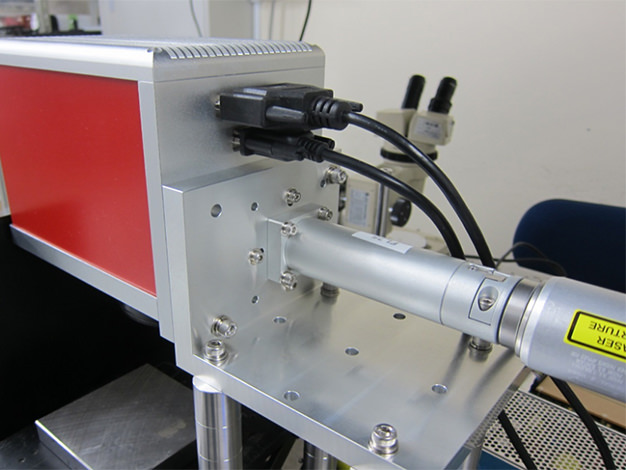

- 8NC data preparation

- Numerical control (NC) data will be prepared based on your approved design.

- 9Blank-material production for the mold or embossing roller

- ▶︎The blank material is heat-treated to be optimal to machine the pattern.

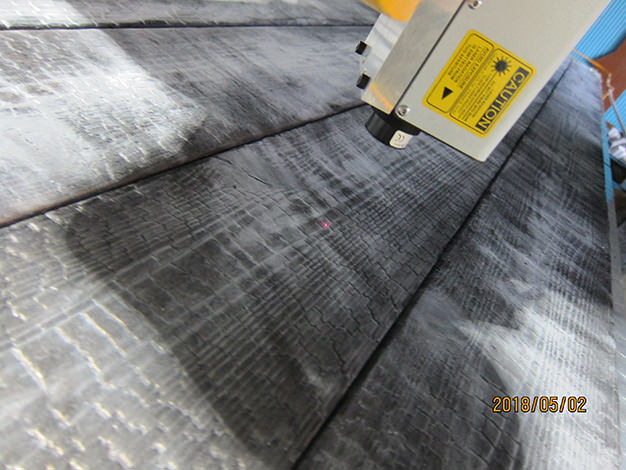

- 10Processing of the resin mold or embossing roller

- ▶︎A resin mold can be used for prototyping before the start of mass production.

- 11Processing of the metal mold or embossing roller

- ▶︎When it is confirmed by the resin mold that mass production can be started, a metal mold is produced.

- 12Finishing, plating, surface treatment, and heat treatment

- ▶︎ The metal mold can be surface-treated by a variety of methods depending on the material.

Inspection and

verification

- 13Inspection and shipment (in Japan or for export)

- An inspection sheet will be prepared, and the product will be shipped by a consolidated or chartered carrier.

- 14Molding observation

- Let us know if the molding process requires our attendance.

- 15Measurement and verification of molded products

- ▶︎ Molded products can be compared with the original data for evaluation.

- 16Secure storage of final product data

- ▶︎(We will retain the final modified design data securely. (Q&A regarding data handling))

After-sales follow-up and maintenance services

We will provide a wide range of after-sales services.